Unveiling the Magic: Crafting Dr. Dabber Vaporizers from Start to Finish

Welcome to the behind-the-scenes journey of Dr. Dabber where innovation meets craftsmanship in the creation of top-notch vaporizers. One interesting thing about Dr. Dabber is that it stands out as a beacon of quality and reliability in the vaping industry.

Ever wondered how these sleek devices come to life? Join us as we pull back the curtain and take you on a captivating tour through the meticulous process of crafting Dr. Dabber vaporizers.

The Birth of an Idea

Every groundbreaking product starts with an idea. A spark of inspiration that sets the wheels in motion. Dr. Dabber often involves a convergence of passion for vaping, technological innovation, and a dedication to elevating the user experience. The team explores various ways to enhance the design and other aspects of the devices to build the best overall performing vaporizers.

As the concept takes shape, prototypes are meticulously crafted and tested. This phase holds its own significance as it allows the workers to focus on the details to ensure that the final product stands out on expectations. This is why the customer satisfaction of Dr. Dabber is always on top.

Precision in Design

The design comes to life when the testing prototype completes all the tests and stages. Dr. Dabber takes pride in its precision, and this is reflected in all aspects of the manufacturing process. The design phase involves not only the external aesthetics but also the internal components that contribute to the vaporizer’s performance.

The group ensures that each element serves a purpose by collaborating with skilled designers and engineers. From the heating chamber to the battery and control system, each part is meticulously crafted to harmonize seamlessly, delivering a product that is both functional and aesthetically pleasing.

Quality Materials Matter

A major factor that sets Dr. Dabber apart is the emphasis on using high-quality materials. The choice of materials significantly influences the durability, performance, and safety of the vaporizer. The makers carefully select materials that not only meet industry standards but also exceed them.

The components used in this stage include:

- Stainless steel

- Ceramic

- Medical-grade components

And other high-quality stuff that remains the center of attention. These materials not only contribute to the sleek and modern design but also ensure that you can enjoy a clean and pure vaping experience. The quality materials underscore Dr. Dabber’s dedication to providing a product that stands the test of time.

The Craftsmanship Behind the Scenes

The manufacturing stage gets triggered once everything is done with the designs and materials. Dr. Dabber is proud of its ability in the craftsmanship that goes into each vaporizer. Skilled artisans and technicians work meticulously to assemble the various components, paying attention to the finest details.

Be it the threading on the mouthpiece or the alignment of internal components, each step is executed with precision. The craftsmanship behind the scenes is a witness to the loyalty of the team to deliver a product that not only meets but exceeds customer expectations..

Fun Fact

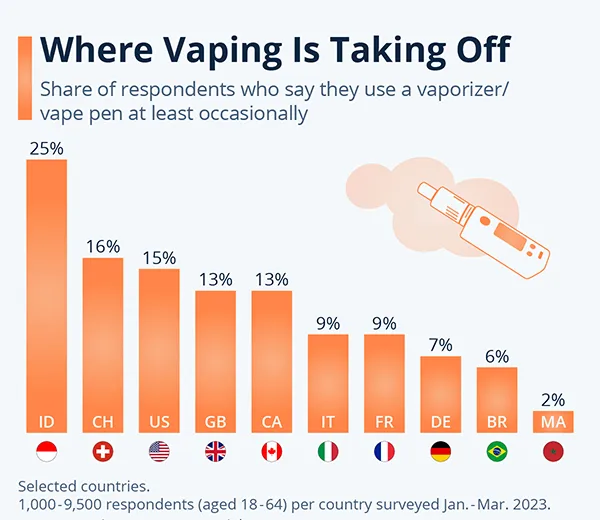

Share of respondents that use vaporizers frequently or occasionally.

Rigorous Testing for Perfection

Quality control is a non-negotiable step in the production of Dr. Dabber vaporizers. Each unit undergoes rigorous testing to ensure it meets the brand’s high standards before reaching the hands of consumers. Functionality, safety, and performance are put to the test through a series of quality control measures.

The testing phase is a vital part of the behind-the-scenes process. It allows the quality workers to identify and address any potential issues before the product reaches the market. This dedication to quality assurance ensures that all Dr. Dabber vaporizers deliver a consistently exceptional experience to users.

Innovation Never Rests

Innovation is the heartbeat that keeps Dr. Dabber ahead of the curve in the current scenario. The research and development team is constantly exploring new technologies, materials, and features to incorporate into future products.

From exploring new heating technologies to integrating smart features, Dr. Dabber remains at the forefront of innovation in the vaping industry. The pushing of boundaries ensures that users can always expect cutting-edge technology in their hands.

Sustainability: A Core Value

For Dr. Dabber, a sustainable environment is one of the top priorities that it focuses on. The company recognizes its responsibility to the environment and takes steps to minimize its ecological footprint. Let it be eco-friendly packaging to energy-efficient manufacturing processes. Sustainability is incorporated into each and every stage of Dr. Dabber’s operations.

Dr. Dabber vaporizers are designed with durability in mind, promoting longevity and reducing the need for frequent replacements. Sustainability extends to the product lifecycle. This eco-conscious approach aligns with the brand’s values and resonates with environmentally-conscious consumers.

DID YOU KNOW?

According to a Truth Initiative study, teen vaping increased 1,800% from 2011 to 2019.

Educating and Empowering Users

At Dr. Dabber, the commitment to the customer extends beyond the purchase of a vaporizer. The company is dedicated to educating and empowering users to ensure that they make informed choices about their vaping experience. The Dab Tools Ultimate Guide https://www.drdabber.com/blogs/news/dab-tools-the-ultimate-guide is a valuable resource for enthusiasts that provides insights into the world of dabbing and vaporization.

From choosing the right tools to understanding the shades of temperature control, the guide covers a range of topics to enhance the user experience. Dr. Dabber believes that an informed user is a satisfied user. The proper education sets the brand apart in an industry that is constantly evolving.

A Symphony of Craftsmanship and Innovation

In conclusion, the journey behind the scenes at Dr. Dabber is a masterpiece. From the initial stage of the idea to the final quality control checks, every step in the process is filled with passion and dedication. As a result, you get a line of vaporizers that not only meet the highest standards but set new benchmarks in the vaping industry.

The pure vapor from a Dr. Dabber device lets you know that it’s more than a product—it’s the result of manufacturing done with excellence. All puffs are a team of dedicated individuals who strive to make your vaping experience exceptional. So, here’s to the creators, the innovators, and the artisans behind the scenes at Dr. Dabber, shaping the future of vaping, one vaporizer at a time.